Manual work must be designed properly so that workers will not overexert themselves and develop muscle strain, especially in the back. Performing heavy physical work for long periods causes the rate of breathing and the heart beat to increase. If a worker is not in good physical condition, he or she is likely to get tired easily while doing heavy physical work. Whenever possible, it is helpful to use mechanical power to do the heavy work. This does not mean that employers should replace workers with machines, rather, that workers can use machines to perform the most arduous tasks.

Mechanical power reduces the risks to the worker and at the same time provides more work opportunities for people with less physical strength.

-Use the following guidelines for designing jobs that require heavy physical work:

-Heavy work should not exceed the capacity of the individual worker.

-Heavy physical work should be varied throughout the day at regular intervals with lighter work.

-Rest periods must be included in the day's work.

-Heavy work should not exceed the capacity of the individual worker.

-Heavy physical work should be varied throughout the day at regular intervals with lighter work.

-Rest periods must be included in the day's work.

Note: a job that requires no physical effort is just as undesirable as a job that only entails heavy physical work. Jobs that require no physical movement are generally tiring and boring.

To design a heavy physical job appropriately, it is important to consider the following factors:

-the weight of the load;

-how often the worker must lift the load;

-the distance of the load from the worker lifting it;

-the shape of the load;

-the length of time required to do the task.

-the weight of the load;

-how often the worker must lift the load;

-the distance of the load from the worker lifting it;

-the shape of the load;

-the length of time required to do the task.

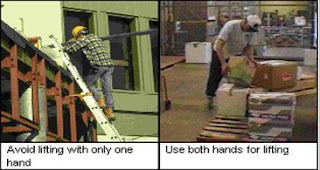

The following are more detailed recommendations for heavy work, especially work that involves lifting. (See picture for guidelines on proper lifting and carrying techniques.)

Reduce the weight of the load:

-repackage to reduce the size;

-reduce the number of objects carried at one time;

-assign more people to lift extra heavy loads.

Make the load easier to handle:

-change the size and shape of the load so that the centre of gravity is closer to the person lifting;

-store the load at or above hip height to avoid the need to bend;

-use mechanical means to raise the load to at least hip height;

-use more than one person or a mechanical device to move the load;

-drag or roll the load with handling aids such as carts, ropes, or slings;

-transfer the weight of the load to stronger parts of the body using handgrips, straps or belts.

Use storage techniques to make handling materials easier:

-use wall brackets, shelving or pallet stands of appropriate height;

-load pallets so that heavy articles are around the edges of the pallet and not in the centre. This will help to distribute weight evenly on the pallet. You must ensure, however, that articles do not easily fall off the pallet and injure someone.

-use wall brackets, shelving or pallet stands of appropriate height;

-load pallets so that heavy articles are around the edges of the pallet and not in the centre. This will help to distribute weight evenly on the pallet. You must ensure, however, that articles do not easily fall off the pallet and injure someone.

Minimize the distance a load must be carried:

-improve the layout of the work area;

-relocate production or storage areas.

-improve the layout of the work area;

-relocate production or storage areas.

Minimize the number of lifts required:

-assign more people to the task;

-use mechanical aids;

-rearrange the storage or work area.

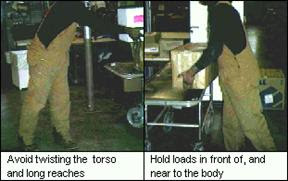

Minimize twisting of the body:

-keep all loads in front of the body;

-allow enough space for the whole body to turn;

-turn by moving the feet rather than twisting the body.

Tiada ulasan:

Catat Ulasan