Ahad, 30 November 2008

Pegawai Keselamatan & Kesihatan vs Pegawai Keselamatan

anda keliru..

AKTA KESELAMATAN DAN KESIHATANPEKERJAAN 1994

PERATURAN-PERATURAN KESELAMATAN DAN KESIHATAN

PEKERJAAN (PEGAWAI KESELAMATAN DAN KESIHATAN) 1997

Pada menjalankan kuasa yang diberikan oleh seksyen 29 dan 66 Akta Keselamatan dan Kesihatan Pekerjaan 1994, Menteri membuat peraturan-peraturan yang berikut:

BAHAGIAN I

PERMULAAN

1.0 Peraturan-peraturan ini bolehlah dinama Peraturan-Peraturan Keselamatan dan Kesihatan Pekerjaan (Pegawai Keselamatan dan Kesihatan) 1997 dan hendaklah mula berkuatkuasa pada 22 Ogos 1997.

2.0 Dalam peraturan-Peraturan ini, melainkan jika konteksnya menghendaki makna yang lain –

“kecederaan masa hilang” ertinya sesuatu kecederaan yang menghalang mana-mana pekerja daripada melaksanakan kerja biasa dan yang menyebabkan ketakupayaan bekerja secara kekal atau sementara.

“tiada kecederaan masa hilang” ertinya sesuatu kecederaan yang tiada kerja yang hilang selain daripada yang dikehendaki bagi rawatan perubatan;

“kemalangan nyaris” ertinya apa-apa kemalangan di tempat kerja yang berpotensi untuk menyebabkan kecederaan kepada mana-mana orang atau kerosakan kepada apa-apa harta;

“Ketua Pengarah” ertinya Ketua Pengarah Keselamatan dan Kesihatan Pekerjaan yang dilantik di bawah subseksyen 5(1) Akta;

“program pendidikan berterusan’ ertinya kursus, seminar, persidangan atau program pendidikan lain dalam keselamatan dan kesihatan pekerjaan atau yang setaraf dengannya, yang diluluskan oleh Ketua Pengarah.

3. Peraturan-Peraturan ini hendaklah terpakai bagi -

(a) seseorang yang bertindak sebagai pegawai keselamatn dan kesihatan yang dikehendaki di bawah Akta atau mana-mana peraturan yang dibuat di bawah Akta,; dan

(b) seseorang majikan bagi kelas atau jenis industri yang diekehendaki mengambil kerja pegawai keselamatan dan kesihatan di bawah Akta.

BAHAGIAN II

PENDAFTARAN PEGAWAI KESELAMATAN DAN KESIHATAN

4. Tiada seorang pun boleh bertindak sebagai pegawai keselamatan dan kesihatan melainkan jika dia telah berdaftar dengan Ketau Pengarah.

5. (1) Setiap permohonan pendaftaran seseorang pegawai keselamatan dan kesihatan hendaklah dibuat dalam Borang sebagaimana yang dinyatakan dalam Jadual I

(2) Permohonan pendaftaran itu hendaklah dikemukakan kepada Ketua Pengarah berserta dengan apa-apa dokumen dan maklumat sebagaimana yang dinyatakan dalam Borang itu disertai dengan fee pemerosesan sebanyak satu ratus ringgit.

6. (1) Seseorang yang –

(a) mempunyai diploma keselamatan dan kesihatan pekerjaan atau yang setaraf dengannya dari mana-mana badan profesional atau institusi, yang diluluskan oleh Menteri, atas syor Ketua Pengarah;

(b) telah berjaya menamatkan kursus latihan dalam keselamatan dan kesihatan pekerjaan dan lulus mana-mana peperiksaan bagi kursus itu atau yang setaraf dengannya, yang diluluskan oleh Menteri, atas syor Ketua Pengarah, dan mempunyai tiga tahun pengalaman minimum dalam keselamatan dan kesihatan pekerjaan;

(c) pernah bekerja dalam bidang keselamatan dan kesihatan pekerjaan sekurang-kurangnya bagi tempoh selama sepuluh tahun; atau

(d) mempunyai kelayakan lain atau telah menerima latihan yang ditetapkan dari semasa ke semasa oleh Menteri menurut subseksyen 29(4) Akta,

berhak, apabila permohonan dibuat olehnya, untuk didaftarkan sebagai pegawai keselamatan dan kesihatan.

(2) Walau apa pun subseksyen (1), seseorang tidak berhak didaftarkan sebagai pegawai keselamatan dan kesihatan jika pada masa permohonan pendaftaran dia telah-

(a) disabitkan dengan mana-mana kesalahan di bawah Akta atau mana-mana peraturan yang dibuat di bawah Akta; atau

(b) disabitkan dengan mana-mana kesalahan dan dihukum lebih daripada satu tahun penjara atau didenda lebih daripada dua ribu ringgit; dan

(c) diisytiharkan bankrap.

(2) Bagi maksud subperenggan (1)(b), kursus Pegawai Keselamatan dan Kesihatan yang dijalankan oleh Institut Keselamatan dan Kesihatan Pekerjaan, Malaysia adalah antara kursus yang diluluskan.

7. Ketua Pengarah hendaklah mengeluarkan kepada seseorang pemohon yang pendaftarannya sebagai pegawai keselamatan dan kesihatan telah diluluskan, suatu perakuan pendaftaran dalam bentuk yang ditetapkan.

8. Seseorang yang telah berdaftar sebagai pegawai keselamatan dan kesihatan hendaklah menghadiri apa-apa program pendidikan berterusan sekurang-kurangnya sekali dalam setahun bagi maksud pembaharuan pendaftaran.

9. Ketua Pengarah boleh enggan mendaftarkan mana-mana permohonan pendaftaran yang dibuat di bawah peraturan 5 jika dia berpuas hati bahawa pemohon tidak memenuhi kehendak-kehendak yang dinyatakan di bawah Peraturan-Peraturan ini atau mana-mana perintah yang dibuat oleh Menteri.

10. Pendaftaran sebagai pegawai keselamatan dan kesihatan adalah sah bagi tempoh selama tiga tahun dari tarikh pendaftaran, melainkan jika ia dibatalkan terlebih dahulu di bawah Peraturan-peraturan ini.

11. Suatu permohonan pembaharuan pendaftaran sebagai pegawai keselamatan dan kesihatan hendaklah dibuat dalam Borang yang dinyatkan dalam Jadual II disertai dengan fee pemerosesan sebanyak lima puluh ringgit.

12. Ketua Pengarah boleh enggan membaharui pendaftaran yang dibuat di bawah peraturan 11 jika pemohon –

(a) telah terhenti menjadi pegawai keselamatan dan kesihata;

(b) adalah pegawai keselamatan dan kesihatan berdaftar yang tidak pernah dilantik sebagai pegawai keselamatan dan kesihatan di bawah Akta sejak pendaftaran atau pembaharuannya;

(c) tidak memenuhi apa-apa kehendak yang dinyatakan di bawah Peraturan-peraturan ini;

(d) telah gagal menjalankan kewajipannya sebagaimana yang dinyatakan di bawah Akta atau mana-mana peraturan yang dibuat di bawah Akta; atau

(e) tidak menunjukkan apa-apa bukti bahawa dia telah menghadiri mana-mana program pendidikan berterusan atau yang setaraf dengannya dalam tempoh tiga tahun yang terakhir sebagaimana yang dikehendaki di bawah peraturan 8.

7. Ketua Pengarah boleh membatalkan pendaftaran seseorang pegawai keselamatan dan kesihatan pada bila-bila masa, jika dia mendapati bahawa pegawai keselamatan dan kesihatan itu –

(a) telah terhenti menjadi pegawai keselamatan dan kesihatan;

(b) telah disabitkan dengan mana-mana kesalahan di bawah Akta atau mana-mana peraturan yang dibuat di bawah Akta;

(c) tidak memenuhi apa-apa kehendak yang dinyatakan di bawah Peraturan-Peraturan ini atau mana-mana perintah yang dibuat oleh Menteri di bawah subseksyen 29(4) Akta; atau

(d) telah memperolehi pendaftaran melalui salah nyataan atau fraud.

BAHAGIAN III

PEMBERITAHUAN MENGENAI PEGAWAI KESELAMATAN

DAN KESIHATAN

14. Seseorang majikan hendaklah memberitahu secara bertulis kepada Ketua Pengarah dalam tempoh satu bulan mengenai apa-apa –

(a) pelantikan seseorang pegawai keselamatan dan kesihatan; atau

(b) penamatan atau peletakan jawatan seseorang pegawai keselamatan dan kesihatan.

BAHAGIAN IV

KEWAJIPAN MAJIKAN

14. Seseorang majikan sesuatu tempat kerja hendaklah menyediakan kepada pegawai keselamatan dan kesihatan yang diambil kerja olehnya, kemudahan-kemudahan yang sesuai termasuk peralatan latiha, dan maklumat yang mencukupi untuk membolehkan pegawai keselamatan dan kesihatan itu menjalankan kewajipannya sebagaimana yang dikehendaki di bawah Akta.

15. Seseorang majikan hendaklah membenarkan pegawai keselamatan dan kesihatan menghadiri apa-apa program pendidikan sekurang-kurang sekali dalam setahun untuk menambah pengetahuannya mengenai keselamatan dan kesihatan pekerjaan.

16. Seseorang majikan hendaklah mengarahkan seorang atau lebih penyelia yang mempunyai kawalan langsung ke atas orang atau aktiviti tempat kerja untuk membantu pegawai keselamatan dan kesihatan dalam mana-mana penyiasatan mengenai kemalangan, kemalangan nyaris, kejadian berbahaya, keracunan pekerjaan atau penyakit pekerjaan.

BAHAGIAN V

KEWAJIPAN PEGAWAI KESELAMATAN DAN KESIHATAN

17. Adalah menjadi kewajipan seseorang pegawai keselamatan dan kesihatan –

(a) untuk menasihati majikan atau mana-mana orang yang bertanggungjawab bagi sesuatu tempat kerja megnenai langkah-langkah yang perlu diambil bagi kepentingan keselamatan dan kesihatan orang-orang yang diambil kerja di tempat kerja itu;

(b) untuk memeriksa tempat kerja untuk menentukan sama ada apa-apa jentera, loji, peralatan, bahan, perkakas atau proses atau apa-apa jenis kerja kasar yang digunakan di tempat kerja, yang boleh menyebabkan kecederaan anggota ke atas mana-mana orang yang bekerja di tempat kerja;

(c) untuk menyiasat apa-apa kemalangan, kamalangan nyaris, kejadian berbahaya, keracunan pekerjaan atau penyakit pekerjaan yang berlaku di tempat kerja;

(d) untuk membantu majikan atau jawatankuasa keselamatan dan kesihatan, jika ada, menurut peraturan 11 Peraturan-Peraturan Keselamatn dan Kesihatan Pekerjaan (Jawatankuasa Keselamatan an Kesihatan) 1996 dalam menganjurkan dan melaksanakan program keselamatan dan kesihatan pekerjaan di tempat kerja;

(e) untuk menjadi setiausaha kepada jawatankuasa keselamatan dan kesihatan jika ada, sebagaimana yang dinyatakan di bawah subperaturan 6(2) Peraturan-Peraturan Keselamatan dan Kesihatan Pekerjaan (Jawatankuasa Keselamatan dan Kesihatan) 1996, dan melaksanakan semua fungsi setiausaha sebagaimana yang dinyatakan dalam Peraturan-Peraturan itu;

(f) untuk membantu jawatankuasa keselamatan dan kesihatan dalam mana-mana pemeriksaan sesuatu tempat kerja bagi maksud memeriksa keberkesanan apa-apa langkah yang diambil bagi mematuhi Akta atau mana-mana peraturan yang dibuat di bawah Akta;

(g) untuk memungut, menganalisis dan menyenggara statistik mengenai apa-apa kemalangan, kejadian berbahaya, keracunan pekerjaan atau penyakit pekerjaan yang berlaku di tempat kerja;

(h) untuk membantu mana-mana pegawai pada menjalankan kewajipannya di bawah Akta atau mana-mana peraturan yang dibuat di bawah Akta; dan

(i) untuk menjalankan apa-apa arahan lain yang dibuat oelh majikan atau mana-mana orang yang bertanggungjawab bagi tempat kerja atas apa-apa perkara yang berkaitan dengan keselamatan dan kesihatan tempat kerja.

19. (1) Seseorang pegawai keselamatan dan kesihatan hendaklah, sebelum hari kesepuluh bulan yang berikutnya, mengemukakan suatu laporan berkaitan dengan aktiviti-aktivitinya kepada majikan.

(2) Laporan yang dikemukakan di bawah subperaturan (1) hendaklah mengandungi, dan tidak terhad kepada perkara-perkara yang berikut:

(a) apa-apa tindakan yang perlu diambil oleh majikan untuk mematuhi kehendak Akta atau mana-mana peraturan yang dibuat di bawah Akta;

(b) cara untuk mewujudkan dan mengekalkan keadaan bekerja yang selamat dan sihat di tempat kerja;

(c) jumlah dan jenis kemalangan, kemalangan nyaris, kejadian berbahaya, keracunan pekerjaan atau penyakit pekerjaan yang berlaku di tempat kerja termasuk jumlah orang yang cedera sama ada melibatkan kecederaan masa hilang atau kecederaan tanpa masa hilang;

(d) apa-apa jentera, loji, peralatan, perkakas, bahan atau proses atau jenis kerja kasar yang digunakan di tempat kerja dan yang boleh menyebabkan kecederaan anggota ke atas mana-mana orang yang bekerja di tempat kerja;

(e) apa-apa jentera, loji, peralatan perkakas, bahan atau apa-apa alat pelindung diri yang dikehendaki bagi maksud mengurangkan apa-apa risiko sedemikian;

(f) mengesyorkan apa-apa pengubahan yang perlu dibuat kepada struktur atau susun atur tempat kerja bagi kepentingan keselamatan dan kesihatan orang yang diambil kerja di dalammnya;

(g) apa-apa kerja yang berhubungan dengan keselamatan dan kesihatan yang telah dijalankan oleh mana-mana orang, atau kumpulan orang yang diambil kerja oleh majikan untuk menggalakkan keselamatan dan kesihatan di tempat kerja;

(h) apa-apa perkara yang belum selesai yang berbangkit daripada laporan yang terdahulu yang dinyatakan di bawah perenggan (a) hingga (g); atau

(i) apa-apa perkara lain yang berhubungan dengan keselamatan dan kesihatan orang yang bekerja di tempat kerja.

20. (1) Seseorang majikan atau mana-mana orang yang bertanggungjawab bagi sesuatu tempat kerja setelah menerima laporan bawah peraturan 19, hendaklah tidak kurang daripada dua minggu selepas menerimanya, membincangkan laporan itu dengan pegawai keselamatan dan kesihatan.

(2) Seseorang majikan atau mana-mana orang yang bertanggungjawab bagi sesuatu tempat kerja hendaklah menanda tangan balas laporan itu untuk mengesahkan yang dia telah menerimanya.

(3) Laporan itu hendaklah disimpan dalam keadaan yang baik sekurang-kurangnya selama tempoh sepuluh tahun bagi maksud pemeriksaan atau penyiasatan oleh pegawai jika perlu.

Egronomics- Material Handling

Manual work must be designed properly so that workers will not overexert themselves and develop muscle strain, especially in the back. Performing heavy physical work for long periods causes the rate of breathing and the heart beat to increase. If a worker is not in good physical condition, he or she is likely to get tired easily while doing heavy physical work. Whenever possible, it is helpful to use mechanical power to do the heavy work. This does not mean that employers should replace workers with machines, rather, that workers can use machines to perform the most arduous tasks.

Mechanical power reduces the risks to the worker and at the same time provides more work opportunities for people with less physical strength.

-Use the following guidelines for designing jobs that require heavy physical work:

-Heavy work should not exceed the capacity of the individual worker.

-Heavy physical work should be varied throughout the day at regular intervals with lighter work.

-Rest periods must be included in the day's work.

-Heavy work should not exceed the capacity of the individual worker.

-Heavy physical work should be varied throughout the day at regular intervals with lighter work.

-Rest periods must be included in the day's work.

Note: a job that requires no physical effort is just as undesirable as a job that only entails heavy physical work. Jobs that require no physical movement are generally tiring and boring.

To design a heavy physical job appropriately, it is important to consider the following factors:

-the weight of the load;

-how often the worker must lift the load;

-the distance of the load from the worker lifting it;

-the shape of the load;

-the length of time required to do the task.

-the weight of the load;

-how often the worker must lift the load;

-the distance of the load from the worker lifting it;

-the shape of the load;

-the length of time required to do the task.

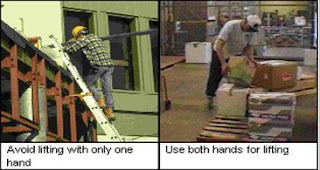

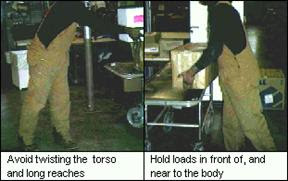

The following are more detailed recommendations for heavy work, especially work that involves lifting. (See picture for guidelines on proper lifting and carrying techniques.)

Reduce the weight of the load:

-repackage to reduce the size;

-reduce the number of objects carried at one time;

-assign more people to lift extra heavy loads.

Make the load easier to handle:

-change the size and shape of the load so that the centre of gravity is closer to the person lifting;

-store the load at or above hip height to avoid the need to bend;

-use mechanical means to raise the load to at least hip height;

-use more than one person or a mechanical device to move the load;

-drag or roll the load with handling aids such as carts, ropes, or slings;

-transfer the weight of the load to stronger parts of the body using handgrips, straps or belts.

Use storage techniques to make handling materials easier:

-use wall brackets, shelving or pallet stands of appropriate height;

-load pallets so that heavy articles are around the edges of the pallet and not in the centre. This will help to distribute weight evenly on the pallet. You must ensure, however, that articles do not easily fall off the pallet and injure someone.

-use wall brackets, shelving or pallet stands of appropriate height;

-load pallets so that heavy articles are around the edges of the pallet and not in the centre. This will help to distribute weight evenly on the pallet. You must ensure, however, that articles do not easily fall off the pallet and injure someone.

Minimize the distance a load must be carried:

-improve the layout of the work area;

-relocate production or storage areas.

-improve the layout of the work area;

-relocate production or storage areas.

Minimize the number of lifts required:

-assign more people to the task;

-use mechanical aids;

-rearrange the storage or work area.

Minimize twisting of the body:

-keep all loads in front of the body;

-allow enough space for the whole body to turn;

-turn by moving the feet rather than twisting the body.

Khamis, 27 November 2008

Skim KWSP ke skim pencen

PUTRAJAYA 27 Nov. – Lebih 40,000 kakitangan awam yang sebelum ini mengambil opsyen skim Kumpulan Wang Simpanan Pekerja (KWSP) boleh menarik nafas lega apabila mereka kini dibenarkan untuk bertukar kepada skim pencen, berkuat kuasa 1 Februari tahun depan.

Perdana Menteri, Datuk Seri Abdullah Ahmad Badawi berkata, kakitangan awam terbabit diberikan peluang selama sebulan untuk membuat pilihan berhubung skim tersebut iaitu dari 1 Januari hingga 31 Januari 2009.

Berucap menyampaikan Anugerah Kualiti Sektor Awam 2008 di sini hari ini, beliau memberitahu, keputusan itu dibuat oleh Jawatankuasa Kabinet Mengenai Perjawatan dan Gaji Pekerja-pekerja Sektor Awam pada mesyuaratnya baru-baru ini.

‘‘Ini tentunya memberikan kebaikan kepada mereka yang terbabit seperti kemudahan perubatan dan memperoleh semua kemudahan yang sama seperti dinikmati oleh para pesara.

‘‘Keduanya, kerajaan juga telah bersetuju untuk memberikan bayaran ex-gratia kepada ibu bapa anggota perkhidmatan awam bujang yang meninggal dunia dalam perkhidmatan dan ia mula berkuat kuasa pada 1 Januari tahun depan,” kata beliau.

Turut hadir Ketua Setiausaha Negara, Tan Sri Mohd. Sidek Hassan; Ketua Pengarah Jabatan Perkhidmatan Awam (JPA), Tan Sri Ismail Adam dan Ketua Pengarah Unit Pemodenan Tadbiran dan Perancangan Pengurusan Malaysia (Mampu), Datuk Normah Md. Yusof.

Pada 1992, melalui Skim Saraan Baru (SSB), kakitangan kerajaan yang dilantik selepas 12 April 1992, ditawarkan skim KWSP sebagai alternatif kepada Skim Pencen seperti yang diperuntukkan dalam Seksyen 6A(1) Akta Pencen 1980 dan Akta Pencen Pihak-Pihak Berkuasa Berkanun dan Tempatan 1980.

Kakitangan awam yang memilih skim KWSP itu bagaimanapun kehilangan faedah gantian cuti rehat, faedah rawatan kesihatan sebagai pesara dan ganjaran persaraan.

Ekoran itu, ramai kakitangan awam merungut bahawa mereka tidak mendapat maklumat jelas semasa hendak membuat opsyen Skim Pencen atau KWSP disebabkan ketiadaan sesi penerangan oleh JPA.

Abdullah seterusnya berkata, kerajaan juga bersetuju membuat penambahbaikan terhadap skim pegawai siasatan, penolong pegawai siasatan dan pembantu pegawai siasatan bagi memperkasakan kegiatan pencegahan rasuah dan membanteras jenayah.

‘‘Bagi urusan pencegahan rasuah, skim perkhidmatan tersebut bermula dengan kelulusan Akta Suruhanjaya Pencegahan Rasuah Malaysia dan bagi Polis Diraja Malaysia (PDRM) pula, penambahbaikan bagi skim perkhidmatan pegawai kanan polis, pegawai rendah polis dan konstabel berkuat kuasa pada 1 Januari 2009,” katanya.

Selain itu, beliau berkata, memandangkan persamaan fungsi dan tugas antara agensi penguatkuasaan maritim Malaysia, tentera laut dan polis daripada aspek penguatkuasaan undang-undang, kerajaan bersetuju agar kadar tambahan 20 peratus atas kadar kenaikan gaji diberi kepada pegawai dan anggota lain-lain pangkat Agensi Penguatkuasa Maritim Malaysia (APMM) berkuat kuasa 1 Januari 2009.

Abdullah berkata, perkhidmatan awam boleh merasa bangga dengan pencapaian itu kerana kerajaan telah menetapkan sasaran untuk melonjakkan kedudukan Malaysia ke taraf 10 teratas dalam mana-mana kategori penarafan antarabangsa.

Dalam pada itu, Abdullah juga mahu pemilihan pemenang anugerah kualiti sektor awam dibuat berasaskan kriteria keunggulan yang mantap serta tahap penilaian yang tinggi agar kewibawaan pemenang terbukti serta tidak dipertikaian mana-mana pihak.

Perdana Menteri, Datuk Seri Abdullah Ahmad Badawi berkata, kakitangan awam terbabit diberikan peluang selama sebulan untuk membuat pilihan berhubung skim tersebut iaitu dari 1 Januari hingga 31 Januari 2009.

Berucap menyampaikan Anugerah Kualiti Sektor Awam 2008 di sini hari ini, beliau memberitahu, keputusan itu dibuat oleh Jawatankuasa Kabinet Mengenai Perjawatan dan Gaji Pekerja-pekerja Sektor Awam pada mesyuaratnya baru-baru ini.

‘‘Ini tentunya memberikan kebaikan kepada mereka yang terbabit seperti kemudahan perubatan dan memperoleh semua kemudahan yang sama seperti dinikmati oleh para pesara.

‘‘Keduanya, kerajaan juga telah bersetuju untuk memberikan bayaran ex-gratia kepada ibu bapa anggota perkhidmatan awam bujang yang meninggal dunia dalam perkhidmatan dan ia mula berkuat kuasa pada 1 Januari tahun depan,” kata beliau.

Turut hadir Ketua Setiausaha Negara, Tan Sri Mohd. Sidek Hassan; Ketua Pengarah Jabatan Perkhidmatan Awam (JPA), Tan Sri Ismail Adam dan Ketua Pengarah Unit Pemodenan Tadbiran dan Perancangan Pengurusan Malaysia (Mampu), Datuk Normah Md. Yusof.

Pada 1992, melalui Skim Saraan Baru (SSB), kakitangan kerajaan yang dilantik selepas 12 April 1992, ditawarkan skim KWSP sebagai alternatif kepada Skim Pencen seperti yang diperuntukkan dalam Seksyen 6A(1) Akta Pencen 1980 dan Akta Pencen Pihak-Pihak Berkuasa Berkanun dan Tempatan 1980.

Kakitangan awam yang memilih skim KWSP itu bagaimanapun kehilangan faedah gantian cuti rehat, faedah rawatan kesihatan sebagai pesara dan ganjaran persaraan.

Ekoran itu, ramai kakitangan awam merungut bahawa mereka tidak mendapat maklumat jelas semasa hendak membuat opsyen Skim Pencen atau KWSP disebabkan ketiadaan sesi penerangan oleh JPA.

Abdullah seterusnya berkata, kerajaan juga bersetuju membuat penambahbaikan terhadap skim pegawai siasatan, penolong pegawai siasatan dan pembantu pegawai siasatan bagi memperkasakan kegiatan pencegahan rasuah dan membanteras jenayah.

‘‘Bagi urusan pencegahan rasuah, skim perkhidmatan tersebut bermula dengan kelulusan Akta Suruhanjaya Pencegahan Rasuah Malaysia dan bagi Polis Diraja Malaysia (PDRM) pula, penambahbaikan bagi skim perkhidmatan pegawai kanan polis, pegawai rendah polis dan konstabel berkuat kuasa pada 1 Januari 2009,” katanya.

Selain itu, beliau berkata, memandangkan persamaan fungsi dan tugas antara agensi penguatkuasaan maritim Malaysia, tentera laut dan polis daripada aspek penguatkuasaan undang-undang, kerajaan bersetuju agar kadar tambahan 20 peratus atas kadar kenaikan gaji diberi kepada pegawai dan anggota lain-lain pangkat Agensi Penguatkuasa Maritim Malaysia (APMM) berkuat kuasa 1 Januari 2009.

Abdullah berkata, perkhidmatan awam boleh merasa bangga dengan pencapaian itu kerana kerajaan telah menetapkan sasaran untuk melonjakkan kedudukan Malaysia ke taraf 10 teratas dalam mana-mana kategori penarafan antarabangsa.

Dalam pada itu, Abdullah juga mahu pemilihan pemenang anugerah kualiti sektor awam dibuat berasaskan kriteria keunggulan yang mantap serta tahap penilaian yang tinggi agar kewibawaan pemenang terbukti serta tidak dipertikaian mana-mana pihak.

bagusla macam ni, tak la kakitangan tertipu..

More EPF members taking out money

PETALING JAYA: The number of people withdrawing their Employees Provident Fund (EPF) accounts in the third quarter of this year has increased by almost 50% compared to the corresponding period last year.

EPF CEO Datuk Azlan Zainol said 107,564 withdrawal applications were approved, a jump of 42.9% from the corresponding period last year. However, the amount disbursed was only RM808.53mil, compared to RM874.44 in the third quarter of last year.

Azlan attributed this to the Basic Savings initiative, which enabled younger members to be eligible for withdrawal.

“Since members can only withdraw up to 20% of the excess amount in their Account 1 funds, younger members will naturally have less funds to withdraw for investment,” he said in a statement.

EPF’s Lump Sum Age 55 Withdrawal remained the most popular option for members who had reached the age of 55, with 29,054 applicants withdrawing a total of RM1,236.14mil.

Under the Flexible Age 55 Withdrawals, which allows members to receive their EPF funds in instalments and on an ad hoc basis rather than as a lump sum, 7,154 members withdrew RM403.51mil.

The take-up rate for the Education Withdrawal remained strong, with 16,663 applications worth RM85.01mil approved, compared with RM87.14mil paid out to 15,877 applicants during the same period last year.

The effects of the economic slowdown is reflected in the decrease of applications for housing withdrawal, with only 108,573 applications approved compared to 135,065.

A total of RM1,577.24mil was disbursed, a drop of 19.5% from RM1,960.32mil from the corresponding quarter last year.

EPF CEO Datuk Azlan Zainol said 107,564 withdrawal applications were approved, a jump of 42.9% from the corresponding period last year. However, the amount disbursed was only RM808.53mil, compared to RM874.44 in the third quarter of last year.

Azlan attributed this to the Basic Savings initiative, which enabled younger members to be eligible for withdrawal.

“Since members can only withdraw up to 20% of the excess amount in their Account 1 funds, younger members will naturally have less funds to withdraw for investment,” he said in a statement.

EPF’s Lump Sum Age 55 Withdrawal remained the most popular option for members who had reached the age of 55, with 29,054 applicants withdrawing a total of RM1,236.14mil.

Under the Flexible Age 55 Withdrawals, which allows members to receive their EPF funds in instalments and on an ad hoc basis rather than as a lump sum, 7,154 members withdrew RM403.51mil.

The take-up rate for the Education Withdrawal remained strong, with 16,663 applications worth RM85.01mil approved, compared with RM87.14mil paid out to 15,877 applicants during the same period last year.

The effects of the economic slowdown is reflected in the decrease of applications for housing withdrawal, with only 108,573 applications approved compared to 135,065.

A total of RM1,577.24mil was disbursed, a drop of 19.5% from RM1,960.32mil from the corresponding quarter last year.

well done to all UTC.

Isnin, 10 November 2008

Socso covers

1. SKIM INSURANS BENCANA PEKERJAAN (SIBP)

1. SKIM INSURANS BENCANA PEKERJAAN (SIBP)PERLINDUNGAN BENCANA KERJA:

a Perjalanan;

- perjalanan berkaitan pekerjaan

b Berpunca dan terbit dari pekerjaan yang dilakukan;

- con: kemalangan mengendalikan mesin di tempat kerja

c Penyakit Khidmat

- akibat pekerjaan yang dilakukan

- con: hilang pendengaran kerana pendedahan bunyi

bising berpanjangan di tempat kerja

- con: penyakit asma kerana terdedah kepada serbuk halus

di kilang papan

FAEDAH SIBP:

- Faedah Perubatan;

- Faedah Hilangupaya Sementara;

- Faedah Hilangupaya kekal;

- Faedah Orang Tanggungan;

- Faedah Pengurusan Mayat;

- Faedah Pemulihan;

- Faedah Pinjaman Pendidikan;

- Elaun Layanan Sentiasa.

2. PERLINDUNGAN PENCEN ILAT:

-Perlindungan 24 jam kepada pekerja terhadap keilatan atau kematian akibat sebarang sebab yang tidak berkaitan dengan pekerjaan.

-Keilatan: suatu keuzuran yang serius, kekal dan tidak boleh atau tidak mungkin sembuh yang mana mengakibatkan seseorang pekerja itu tidak mampu mencari nafkah sekurang-kurangnya satu pertiga daripada keupayaan seseorang pekerja yang normal.

-Di antara penyakit-penyakit kronik penyebab keilatan yang boleh dipertimbangkan ialah seperti sakit jantung, masalah buah pinggang, barah, sakit jiwa, asma yang teruk dan sebagainya.

FAEDAH SPI:

- Pencen Ilat;

- Bantuan Ilat;

- Elaun Layanan Sentiasa;

- Pencen Penakat;

- Faedah Pengurusan Mayat;

- Faedah Pemulihan;

- Faedah Pinjaman Pendidikan.

PENILAIAN KECACATAN

HILANGUPAYA SEPARA YANG KEKAL:

-Hilangupaya yang berkekalan hingga mengurangkan upaya mencari nafkah seseorang pekerja dalam segala pekerjaan yang ia sanggup menjalankan pada masa kemalangan yang mengakibatkan hilangupaya itu.

-Dengan syarat bahawa tiap-tiap bencana yang dinyatakan dalam Bahagian 2 dalam Jadual Kedua AKTA KSP hendaklah disifatkan sebagai mengakibatkan hilangupaya separa yang kekal.

HILANGUPAYA LANGSUNG YANG KEKAL:

-Apa-apa hilangupaya yang berkekalan hingga menghilangkan upaya seseorang pekerja menjalankan segala kerja yang ia boleh jalankan pada masa kemalangan yang mengakibatkan hilangupaya itu.

-Dengan syarat bahawa hilangupaya langsung yang kekal hendaklah disifatkan sebagai diakibatkan oleh tiap-tiap bencana yang dinyatakan dalam Bahagian 1 dalam Jadual Kedua AKTA KSP atau campuran bencana-bencana yang dinyatakan dalam Bahagian 2.

NOISE EXPOSURE

•Prolonged exposure to high noise level can cause permanent hearing impairment.

•This type of hearing impairment is incurable and the effects are gradual.

•Beside that, noise can also cause negatives effects such :

–Speech interference

•Loss of concentration

–Annoyance/ Angry

–Headache

–Stress

•This type of hearing impairment is incurable and the effects are gradual.

•Beside that, noise can also cause negatives effects such :

–Speech interference

•Loss of concentration

–Annoyance/ Angry

–Headache

–Stress

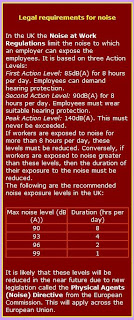

Legal Compliance

•Factories and Machinery ( Noise Exposure) Regulations 1989.

•Shall apply to all factories in which employees are exposed to excessive noise level in the workplace.

•In pursuance of these regulations, every employee shall :

-cooperate by wearing a noise

dosimeter during noise exposure monitoring.

-attend training and information programmes

PERMISSIBLE EXPOSURE LIMIT

1.No employee shall be exposed to noise level exceeding :-

a. Equivalent continuous sound

level of 90dB(A).

b. 115dB(A) at any time.

c. Impulsive noise exceeding a

peak sound pressure level of

140dB.

a. Equivalent continuous sound

level of 90dB(A).

b. 115dB(A) at any time.

c. Impulsive noise exceeding a

peak sound pressure level of

140dB.

NOISE CONTROL PROGRAMMES

1.Shall always ensure that no employees are exposed to noise level exceeding action level of 90dB(A).

2.Conduct noise reduction via Engineering control on :

- Eyelet machine

- VCD & DHJW machine

- RH II AND RHU

3. Administrative control:

•Employee rotate in taking care of machine with loud noise example take care of 1 loud machine and 1 low sound machine.

•Change PIC every year – in taking care of high noise level machine

EMPLOYER`S RESPONSIBILITIES

•To reduce noise level by engineering method and ensure legal compliance.

•By conducting monitoring as required in the regulations

Shall conduct audiometric hearing test to employees (upon assessment of occupational health doctor).

EMPLOYEES RESPONSIBILITIES

•Understand Noise Regulation- to protect them.

•Ensure correct method of working – closure of machine during operating.

•Report all complaints of hearing loss to in-plant clinic.

•Cooperate during noise exposure monitoring.

Pemberitahuan Kemalangan, Kejadian Berbahaya, Keracunan Pekerjaan dan Penyakit Pekerjaan

PENDAHULUAN

Peraturan-Peraturan Keselamatan dan Kesihatan Pekerjaan (Pemberitahuan Kemalangan, Kejadian Berbahaya, Keracunan Pekerjaan dan Penyakit Pekerjaan) sedang digubal olek Kerajaan dan dijangka akan diwarta pada penghujung tahun 1998. Oleh itu kertas kerja ini disediakan terlebih dahulu berdasarkan kepada peruntukan-peruntukan yang sediaada di bawah kehendak Akta Keselamatan dan Kesihatan Pekerjaan 1994, terutamanya Akta Kilang dan Jentera 1967.

TUJUAN

Peruntukan Akta Keselamatan dan Kesihatan Pekerjaan 1994 mengkehendaki setiap majikan;

(i) Menyediakan suatu saluran komunikasi untuk membolehkan mana-mana pekerjanya membuat aduan mengenai apa-apa perkara yang memudaratkan keselamatan dan kesihatan di tempat kerja

(ii) Menjalankan siasatan keatas apa-apa kemalangan, kemalangan nyaris, kejadian berbahaya, keracunan atau penyakit pekerjaan dan aduan yang tersebut diatas di tempat kerja masing-masing

(iii) Mengambil tindakan yang sewajarnya keatas aduan dan kejadian yang tersebut diatas

(iv) Melaporkan kejadian yang tersebut diatas kepada Jabatan Keselamatan dan Kesihatan Pekerjaan Malaysia

(i) Menyediakan suatu saluran komunikasi untuk membolehkan mana-mana pekerjanya membuat aduan mengenai apa-apa perkara yang memudaratkan keselamatan dan kesihatan di tempat kerja

(ii) Menjalankan siasatan keatas apa-apa kemalangan, kemalangan nyaris, kejadian berbahaya, keracunan atau penyakit pekerjaan dan aduan yang tersebut diatas di tempat kerja masing-masing

(iii) Mengambil tindakan yang sewajarnya keatas aduan dan kejadian yang tersebut diatas

(iv) Melaporkan kejadian yang tersebut diatas kepada Jabatan Keselamatan dan Kesihatan Pekerjaan Malaysia

TAKRIFAN

Beberapa tafsiran berkenaan berdasarkan Akta Keselamatan dan Kesihatan Pekerjaan 1994 dan Akta Kilang dan Jentera 1967

1. Kejadian Berbahaya (Dangerous Occurrence)

Mana-mana kejadian didalam mana-mana kelas yang disenaraikan pada Jadual Pertama Akta Kilang dan Jentera 1967 sebagaimana yang dilampirkan

1. Kejadian Berbahaya (Dangerous Occurrence)

Mana-mana kejadian didalam mana-mana kelas yang disenaraikan pada Jadual Pertama Akta Kilang dan Jentera 1967 sebagaimana yang dilampirkan

-Bursting of a revolving vessel, wheel, grindstone or grinding wheel moved by mechanical power.

-Collapse or failure of a crane, derrick, winch, hoist, piling frame or other appliance used in raising or lowering persons or goods, or any part thereof (except breakage of chain or rope slings), or the overturning of a crane.

-Explosion or fire or failure of structure affecting the safety or strength of any room or place in which persons are employed, or to any machinery of plant contained therein.

-Explosion or failure of structure affecting the safety or strength of a steam boiler or of an unfired pressure vessel; the lose of boiler water, the melting of a fusible plug and the bursting of a tube.

2. Penyakit Pekerjaan (Occupational Diseases)

Mana-mana penyakit yang disenaraikan dalam Jadual Ketiga Akta Kilang dan Jentera 1967 atau mana-mana penyakit yang dinamakan dalam mana-mana peraturan atau perintah yang dibuat dibawah Akta Keselamatan dan Kesihatan 1994

-Collapse or failure of a crane, derrick, winch, hoist, piling frame or other appliance used in raising or lowering persons or goods, or any part thereof (except breakage of chain or rope slings), or the overturning of a crane.

-Explosion or fire or failure of structure affecting the safety or strength of any room or place in which persons are employed, or to any machinery of plant contained therein.

-Explosion or failure of structure affecting the safety or strength of a steam boiler or of an unfired pressure vessel; the lose of boiler water, the melting of a fusible plug and the bursting of a tube.

2. Penyakit Pekerjaan (Occupational Diseases)

Mana-mana penyakit yang disenaraikan dalam Jadual Ketiga Akta Kilang dan Jentera 1967 atau mana-mana penyakit yang dinamakan dalam mana-mana peraturan atau perintah yang dibuat dibawah Akta Keselamatan dan Kesihatan 1994

- Dust diseases of the lungs :

(a) Silicosis – inhalation of (SiO2) silica containing dust

(b) Stannosis – inhalation of tin dusts or fumes

(c) Sidersosis or sidero – silicosis inhalation of dust containing iron and silica, haematite

(d) Asbestosis – inhalation of asbestos dust or fibres

(e) Conditions of respiratory allergy of asthma or chronic bronchitis, or byssinosis resulting from inhalation of dusts of plants origin as cotton, wood, flax, jute, rice husks, cork, spices, hemp, sisal, tobacco, tea, flour and the like and mineral dusts as cements, copper, zinc, or animal dusts as bone or hair.

(f) Other pneumoconiosis or fibriotic diseases of the lungs resulting from inhalation of aluminium, talc or coals

(a) Silicosis – inhalation of (SiO2) silica containing dust

(b) Stannosis – inhalation of tin dusts or fumes

(c) Sidersosis or sidero – silicosis inhalation of dust containing iron and silica, haematite

(d) Asbestosis – inhalation of asbestos dust or fibres

(e) Conditions of respiratory allergy of asthma or chronic bronchitis, or byssinosis resulting from inhalation of dusts of plants origin as cotton, wood, flax, jute, rice husks, cork, spices, hemp, sisal, tobacco, tea, flour and the like and mineral dusts as cements, copper, zinc, or animal dusts as bone or hair.

(f) Other pneumoconiosis or fibriotic diseases of the lungs resulting from inhalation of aluminium, talc or coals

-Systematic intoxication by any of the following metals or their compounds, lead, mercury, manganese, phosphorous, antimony, chromium, nickel, beryllium.

-Intoxication resulting from the use of solvents, benzene and other aromatic hydrocarbons and petroleum and its derivatives.

-Pulmonary irritation resulting from inhalation of nitrogen oxides, sulphur oxides, chlorine, phosgene, ammonia, etc.

-Intoxication resulting from handling of insecticides, or herbicides or fungicides as organic phosphate compounds, nitrogenous and chlorinated compounds.

-Conditions of occupational dermatosis resulting from handling of mineral oils, acids, alkalis, dusts and other irritants.

-Occupational infections as anthrax, glanders, leptospirosis, tuberculosis, leptrosy (where occupational exposure to the last two is evident)

-Malignant disease resulting from handling or inhalation or contact with carcinogenic tars or radioactive dusts.

-Eye conditions resulting from physical trauma as heat cataract, radiation cataract and from irritants.

-Toxic jaundice resulting from nitro or amino derivatives of benzene or other substances.

-Subcutaneous or acute bursitis of knee or hand or wrist resulting from manual labour causing severe or prolonged friction or pressure.

-Conditions resulting from severe heat exposure such as heat cramps or heat stroke.

-Hearing loss due to excessive exposure to industrial noise of high sound pressure level.

-Conditions resulting from exposure to ionizing and non-ionizing radiation.

-Decompression sickness (caisson disease) and conditions resulting from working and under water.

-Intoxication resulting from the use of solvents, benzene and other aromatic hydrocarbons and petroleum and its derivatives.

-Pulmonary irritation resulting from inhalation of nitrogen oxides, sulphur oxides, chlorine, phosgene, ammonia, etc.

-Intoxication resulting from handling of insecticides, or herbicides or fungicides as organic phosphate compounds, nitrogenous and chlorinated compounds.

-Conditions of occupational dermatosis resulting from handling of mineral oils, acids, alkalis, dusts and other irritants.

-Occupational infections as anthrax, glanders, leptospirosis, tuberculosis, leptrosy (where occupational exposure to the last two is evident)

-Malignant disease resulting from handling or inhalation or contact with carcinogenic tars or radioactive dusts.

-Eye conditions resulting from physical trauma as heat cataract, radiation cataract and from irritants.

-Toxic jaundice resulting from nitro or amino derivatives of benzene or other substances.

-Subcutaneous or acute bursitis of knee or hand or wrist resulting from manual labour causing severe or prolonged friction or pressure.

-Conditions resulting from severe heat exposure such as heat cramps or heat stroke.

-Hearing loss due to excessive exposure to industrial noise of high sound pressure level.

-Conditions resulting from exposure to ionizing and non-ionizing radiation.

-Decompression sickness (caisson disease) and conditions resulting from working and under water.

3. Kemalangan Nyaris (Near Miss)

Apa-apa kemalangan di tempat kerja yang berpotensi untuk menyebabakan kecederaan kepada mana-mana orang atau kerosakan kepada apa-apa harta

Apa-apa kemalangan di tempat kerja yang berpotensi untuk menyebabakan kecederaan kepada mana-mana orang atau kerosakan kepada apa-apa harta

LAPORAN

Setiap kemalangan, kemalangan nyaris, kejadian berbahaya, keracunan pekerjaan atau penyakit pekerjaan yang berlaku di tempat kerja masing-masing hendaklah dilaporkan kepada Jawatankuasa Keselamatan dan Kesihatan Pekerjaan. Laporan tersebut hendaklah dibuat dengan serta merta sebaik sahaja kejadian tersebut dikenalpasti atau berlaku.

Pegawai Keselamatan dan Kesihatan Pekerjaan sebaik sahaja menerima laporan/aduan tersebut hendaklah menjalankan siasatan awal kejadian/aduan tersebut. Siasatan tersebut hendaklah mendapatkan dimana yang perlu ada maklumat-maklumat dan keterangan daripada individu yang terlibat secara langsung, mangsa kemalangan, saksi kemalangan atau mereka yang berkenaan dengan menggunakan borang laporan kejadian dan mengambil gambar-gambar photo dan bahan-bahan bukti kejadian.

Ahad, 9 November 2008

Accident Prevention

WORKPLACE ACCIDENTS

They Cost More Than You Might Think

The indirect costs of industrial accidents which take into account the sometimes immeasurable costs of lost production and efficiency on a company-wide basis-can be several times the costs of calculable workers' compensation and employee disability payments. These costs, however, are unnecessary. A recently released study notes that about 85 percent of all workplace injuries and fatalities can be avoided by making sure employees have been properly trained for their jobs-by introducing and requiring all employees to adhere to safe workplace practices, and by getting managers as well as the operational staff to make a genuine commitment to worker safety.

The accident took place in an instant. The worker received prompt first-aid attention and the injury was treated. The after-effects of the accident, however, transpired more slowly. Workers who witnessed the scene were too shaken up to resume their duties. Production stopped until the damaged equipment was cleared and replaced with new machinery. Managers reassigned the injured worker, called in a replacement, and explained the duties. The supervisor filled out a lengthy accident report and several regulatory forms. The plant owner prepared for possible litigation. What are the cost implications of these interrelated events? In most cases, such accidents and the accompanying loss of production and efficiency can be avoided by establishing manager/employee safety committees, instituting regular training programs and inspections, conducting emergency drills, and other steps. Certainly the most quantifiable benefit resulting from the successful introduction of a safety program is a reduction in workers' compensation insurance rates. Less measurable benefits, however, involve the avoidance of the indirect costs of an accident

Indirect costs

The indirect costs of an accident take into effect the sometimes immeasurable costs of lost production and efficiency on a company-wide basis. They include the following costs Wages for lost time of uninjured co-workers. Workers adjacent to the accident scene who stop their work to watch or offer assistance or talk about the accident need to be considered when assessing the financial impact of an accident. Repair or replacement of damaged material or equipment. This includes the time to order, deliver, and test the new machine following the accident.

Training replacement workers. Recruiting and training temporary or permanent workers-and all the costs incurred by administrative personnel-need to be considered. Overtime. Extra costs of employee overtime to make up lost production frequently occur after a workplace accident.

Other indirect costs of an accident also result in loss of productivity, including the following: Foreman's diverted activity. Supervisory wages for time attending to the accident must be assigned to the total costs of the accident. Wages spent on reduced production. The cost of wages for an injured worker's return to a job could also be a factor, if the worker's performance decreases. Clerical supervision and accident investigation. Filing accident and investigation reports to insurance company and regulatory agencies, and the expense of accident investigation and recommendations for preventive measures, are to be considered. Remedial and compliance costs for equipment safeguards. Following the event, response to regulatory hearings and equipment modifications for compliance can be costly, including special safety training, procedures, and monitoring of results as directly related to the accident.

Cost of criminal negligence

There is a potential cost experienced by high-level executives who might be found guilty of violating workplace safety regulations. In the United States legislation allows senior executives to be goaled for breaches of workplace health and safety and THEY HAVE BEEN! Consider the outcome of the tragic 1991 fire at Imperial Food Products' poultry processing plant in North Carolina. In what has been one of the worst industrial accidents in the state's history, 25 workers were killed and 50 injured because of illegally locked or blocked doors. A federal judge ordered the insurance companies to pay US$18.1 million to settle claims and, as a result of the safety violations, Imperial Food's owner was sentenced to 19 years in prison on 25 counts of manslaughter.

In yet another example, from the litigious United States, the Illinois Supreme Court ordered five senior officials of Chicago Magnet Wire Co. to stand trial on criminal charges that they were responsible for job-related injuries to their employees. The decision stems from charges against the officials of allowing more than 40 workers to become ill from exposure to a dozen hazardous chemicals. Legal experts say the decision is likely to lead to additional charges against corporate officials in worker injury cases in other states.

Before we get to smug in the Antipodes it is important to realise that the State of Victoria has “Industrial Manslaughter” as a charge and there have been managers charged. In most other states the jurisdiction does allow for imprisonment; although we are yet to see it applied. Maybe it is “about time”.

The real story

According to the National Safety Council, the indirect costs of industrial accidents are approximately four times the actual direct costs. In other words, the real costs of workplace injuries are several times the calculable workers' compensation and employee disability payments. When this calculation is combined with the potential costs incurred by executives in defending against criminal negligence, the true cost of workplace injuries becomes staggering. These costs, however, are unnecessary. A recently released study notes that about 85 percent of all workplace injuries and fatalities can be avoided. The findings state that most workplace accidents and injuries stem from human error or inattention that can be prevented by making sure employees have been properly trained for their jobs, by introducing and requiring all employees to adhere to safe workplace practices, and by getting managers as well as the operational staff to make a genuine commitment to worker safety Interestingly, the factors listed are among the components the NSW Consolidated Regulation of 2001 advocates.. Study after study has shown the crucial role that management plays in effective safety programs. Such concern is manifest in a number of ways: appointment of a high-level safety officer, rewards to supervisors on the basis of the safety records of their subordinates, and comparison of safety results against preset objectives. Management's good example completes a loss control program. If hard hats are required at a particular operation, then executives should wear hard hats too. If employees see executives disregarding safety rules or treating hazardous situations lightly by not conforming to regulations, then they will feel that they also have the right to violate the rules. In short, organisations show their concern for loss control by establishing a clear safety policy and by assuming responsibility for its implementation.

The biggest “stumbling block” is the manager who makes “all the right noises” but in their observed practice continues to place other factors, such as productivity, as a higher priority Operational staff see this dichotomy (some might go so far as to suggest hypocrisy) and behave accordingly in their own approach to safety management.

Essential steps to safety

Investing in a safer workplace cuts the expense of treating injured workers and helps companies control insurance premiums and prevent workplace accidents. Equally important, effective safety standards in the workplace boost employee morale by conveying the message that the company cares enough about its people to protect their health and safety. Safety problems can be easily and inexpensively avoided by taking the following steps:

Tighten up housekeeping.

It sounds simple, but such activities as keeping floors swept and obstacles out of the way make a major contribution to reducing the number of accidents in both factories and offices. Pay special attention to seemingly harmless items that can easily become hazards e.g., water spilled around a water cooler or pathways obstructed by wires or boxes. Conduct regular safety checks. Unless your company is large enough to hire a full- or part-time risk manager, consider retaining a safety consultant to inspect the premises once or twice a year. To find one, consult your insurance company. It may offer to do the inspections or suggest other specialists. The cost is typically $300 to $400 for one day--the time required to make a safety inspection at most small companies. Conduct regular fire drills. If you retain a safety consultant, ask for suggestions on the frequency of fire drills. As a rule, businesses need drills two or three times a year, but some types of companies handling flammable materials should hold drills more often.

Train employees to be safety conscious.

Alert workers to areas that pose potential safety risks, such as stairways and light fixtures. Many accidents can be avoided by orienting new employees to their environment or by reminding current workers of past accidents and procedures for avoiding them in the future.

Continuously improve safety training. Few companies would let untrained employees operate heavy machinery, but a surprising number allow them to use everyday office equipment that can also cause injury. Training basics include instructing all employees in safe machine operation, stating safety procedures in employee handbooks, and supporting employees in first aid training offered by the St John’s Ambulance or Red Cross etc. Each of these suggestions can be implemented inexpensively and has reduced workplace injuries in organisations of all sizes.

Real-life benefits

An example of this positive outcome was seen within a local government organisation that I provided services to. The organisation cut workers' compensation premiums by more than $200,000 after experiencing a significant reduction in accident frequency and severity. In addition far more structured programs for assistance with workplace reintegration were implemented which resulted in a Return to Work Rate of 100% over three years. Unfortunately this organisation made a decision to modify its approach to safety management and is now confronting increasing costs again. As your company undertakes a safety program, consider the cost/benefit analysis outlined above. Beyond mere regulatory compliance, you have a number of options regarding the degree to which your company invests in employee safety. Underlying these efforts is a conviction on the part of many firms that it is morally right to improve job safety and health; and that doing so will enhance the productivity and quality of work life of employees at all levels.

They Cost More Than You Might Think

The indirect costs of industrial accidents which take into account the sometimes immeasurable costs of lost production and efficiency on a company-wide basis-can be several times the costs of calculable workers' compensation and employee disability payments. These costs, however, are unnecessary. A recently released study notes that about 85 percent of all workplace injuries and fatalities can be avoided by making sure employees have been properly trained for their jobs-by introducing and requiring all employees to adhere to safe workplace practices, and by getting managers as well as the operational staff to make a genuine commitment to worker safety.

The accident took place in an instant. The worker received prompt first-aid attention and the injury was treated. The after-effects of the accident, however, transpired more slowly. Workers who witnessed the scene were too shaken up to resume their duties. Production stopped until the damaged equipment was cleared and replaced with new machinery. Managers reassigned the injured worker, called in a replacement, and explained the duties. The supervisor filled out a lengthy accident report and several regulatory forms. The plant owner prepared for possible litigation. What are the cost implications of these interrelated events? In most cases, such accidents and the accompanying loss of production and efficiency can be avoided by establishing manager/employee safety committees, instituting regular training programs and inspections, conducting emergency drills, and other steps. Certainly the most quantifiable benefit resulting from the successful introduction of a safety program is a reduction in workers' compensation insurance rates. Less measurable benefits, however, involve the avoidance of the indirect costs of an accident

Indirect costs

The indirect costs of an accident take into effect the sometimes immeasurable costs of lost production and efficiency on a company-wide basis. They include the following costs Wages for lost time of uninjured co-workers. Workers adjacent to the accident scene who stop their work to watch or offer assistance or talk about the accident need to be considered when assessing the financial impact of an accident. Repair or replacement of damaged material or equipment. This includes the time to order, deliver, and test the new machine following the accident.

Training replacement workers. Recruiting and training temporary or permanent workers-and all the costs incurred by administrative personnel-need to be considered. Overtime. Extra costs of employee overtime to make up lost production frequently occur after a workplace accident.

Other indirect costs of an accident also result in loss of productivity, including the following: Foreman's diverted activity. Supervisory wages for time attending to the accident must be assigned to the total costs of the accident. Wages spent on reduced production. The cost of wages for an injured worker's return to a job could also be a factor, if the worker's performance decreases. Clerical supervision and accident investigation. Filing accident and investigation reports to insurance company and regulatory agencies, and the expense of accident investigation and recommendations for preventive measures, are to be considered. Remedial and compliance costs for equipment safeguards. Following the event, response to regulatory hearings and equipment modifications for compliance can be costly, including special safety training, procedures, and monitoring of results as directly related to the accident.

Cost of criminal negligence

There is a potential cost experienced by high-level executives who might be found guilty of violating workplace safety regulations. In the United States legislation allows senior executives to be goaled for breaches of workplace health and safety and THEY HAVE BEEN! Consider the outcome of the tragic 1991 fire at Imperial Food Products' poultry processing plant in North Carolina. In what has been one of the worst industrial accidents in the state's history, 25 workers were killed and 50 injured because of illegally locked or blocked doors. A federal judge ordered the insurance companies to pay US$18.1 million to settle claims and, as a result of the safety violations, Imperial Food's owner was sentenced to 19 years in prison on 25 counts of manslaughter.

In yet another example, from the litigious United States, the Illinois Supreme Court ordered five senior officials of Chicago Magnet Wire Co. to stand trial on criminal charges that they were responsible for job-related injuries to their employees. The decision stems from charges against the officials of allowing more than 40 workers to become ill from exposure to a dozen hazardous chemicals. Legal experts say the decision is likely to lead to additional charges against corporate officials in worker injury cases in other states.

Before we get to smug in the Antipodes it is important to realise that the State of Victoria has “Industrial Manslaughter” as a charge and there have been managers charged. In most other states the jurisdiction does allow for imprisonment; although we are yet to see it applied. Maybe it is “about time”.

The real story

According to the National Safety Council, the indirect costs of industrial accidents are approximately four times the actual direct costs. In other words, the real costs of workplace injuries are several times the calculable workers' compensation and employee disability payments. When this calculation is combined with the potential costs incurred by executives in defending against criminal negligence, the true cost of workplace injuries becomes staggering. These costs, however, are unnecessary. A recently released study notes that about 85 percent of all workplace injuries and fatalities can be avoided. The findings state that most workplace accidents and injuries stem from human error or inattention that can be prevented by making sure employees have been properly trained for their jobs, by introducing and requiring all employees to adhere to safe workplace practices, and by getting managers as well as the operational staff to make a genuine commitment to worker safety Interestingly, the factors listed are among the components the NSW Consolidated Regulation of 2001 advocates.. Study after study has shown the crucial role that management plays in effective safety programs. Such concern is manifest in a number of ways: appointment of a high-level safety officer, rewards to supervisors on the basis of the safety records of their subordinates, and comparison of safety results against preset objectives. Management's good example completes a loss control program. If hard hats are required at a particular operation, then executives should wear hard hats too. If employees see executives disregarding safety rules or treating hazardous situations lightly by not conforming to regulations, then they will feel that they also have the right to violate the rules. In short, organisations show their concern for loss control by establishing a clear safety policy and by assuming responsibility for its implementation.

The biggest “stumbling block” is the manager who makes “all the right noises” but in their observed practice continues to place other factors, such as productivity, as a higher priority Operational staff see this dichotomy (some might go so far as to suggest hypocrisy) and behave accordingly in their own approach to safety management.

Essential steps to safety

Investing in a safer workplace cuts the expense of treating injured workers and helps companies control insurance premiums and prevent workplace accidents. Equally important, effective safety standards in the workplace boost employee morale by conveying the message that the company cares enough about its people to protect their health and safety. Safety problems can be easily and inexpensively avoided by taking the following steps:

Tighten up housekeeping.

It sounds simple, but such activities as keeping floors swept and obstacles out of the way make a major contribution to reducing the number of accidents in both factories and offices. Pay special attention to seemingly harmless items that can easily become hazards e.g., water spilled around a water cooler or pathways obstructed by wires or boxes. Conduct regular safety checks. Unless your company is large enough to hire a full- or part-time risk manager, consider retaining a safety consultant to inspect the premises once or twice a year. To find one, consult your insurance company. It may offer to do the inspections or suggest other specialists. The cost is typically $300 to $400 for one day--the time required to make a safety inspection at most small companies. Conduct regular fire drills. If you retain a safety consultant, ask for suggestions on the frequency of fire drills. As a rule, businesses need drills two or three times a year, but some types of companies handling flammable materials should hold drills more often.

Train employees to be safety conscious.

Alert workers to areas that pose potential safety risks, such as stairways and light fixtures. Many accidents can be avoided by orienting new employees to their environment or by reminding current workers of past accidents and procedures for avoiding them in the future.

Continuously improve safety training. Few companies would let untrained employees operate heavy machinery, but a surprising number allow them to use everyday office equipment that can also cause injury. Training basics include instructing all employees in safe machine operation, stating safety procedures in employee handbooks, and supporting employees in first aid training offered by the St John’s Ambulance or Red Cross etc. Each of these suggestions can be implemented inexpensively and has reduced workplace injuries in organisations of all sizes.

Real-life benefits

An example of this positive outcome was seen within a local government organisation that I provided services to. The organisation cut workers' compensation premiums by more than $200,000 after experiencing a significant reduction in accident frequency and severity. In addition far more structured programs for assistance with workplace reintegration were implemented which resulted in a Return to Work Rate of 100% over three years. Unfortunately this organisation made a decision to modify its approach to safety management and is now confronting increasing costs again. As your company undertakes a safety program, consider the cost/benefit analysis outlined above. Beyond mere regulatory compliance, you have a number of options regarding the degree to which your company invests in employee safety. Underlying these efforts is a conviction on the part of many firms that it is morally right to improve job safety and health; and that doing so will enhance the productivity and quality of work life of employees at all levels.

EPF contributions will be reduced

The govt has announced that w.e.f. Jan 09, EPF contributions will be reduced from 11% of their salary to 8% for 2 years. This is to give employees more disposable income (YES! The word is “disposable”) to increase household spending to stimulate the economy. It will be applied to all employees. Those who wish to maintain the 11% contribution have to apply thro a special form.

The govt has announced that w.e.f. Jan 09, EPF contributions will be reduced from 11% of their salary to 8% for 2 years. This is to give employees more disposable income (YES! The word is “disposable”) to increase household spending to stimulate the economy. It will be applied to all employees. Those who wish to maintain the 11% contribution have to apply thro a special form.Several bodies including CUEPACS are against this reduction as it means less household savings.

If the reduction goes through in Jan 09, we have a great opportunity to get our friends/prospects/investors to put the 3% into a monthly DDI so that they will not spend it.

If they do not want us to know how much they earn, let’s be sensitive & suggest a figure.

As our minimum monthly investment is RM100, it would mean that those with monthly salary of RM3,333 will have an extra RM100 net take-home pay. Those who earn

& use amounts like RM338 or $555, reason we give them is that it will be easier to identify the amount in our bank account. Every additional RM38 or RM55 u can get will increase your total monthly DDI be a lot!

Advantages of DDI Sales:

Ø Building up your DDI sales will build up a passive income for u gradually as the monthly amounts are automatically invested with no further effort from u or the investor.

Ø Investors will not feel the pinch as the monthly amounts are small but the cumulative amounts eventually will be substantial.

Ø U can ask for increase of the monthly amount when investors have more income later.

Ø U can also ask for additional DDI investments when investor has a new child, etc.

Ø Investors get to accumulate more units in the long run becoz of DCA (dollar-cost-averaging).

Ø DCA effect will mean that investors will not suffer big unrealized losses when markets are down.

The best tools to use to close monthly DDI would be “Cost of Procrastination & Dollar Cost Averaging

P/s who want to remain contribution 11%, please fill in and submit form KWSP 17A (AHL).

Langgan:

Catatan (Atom)